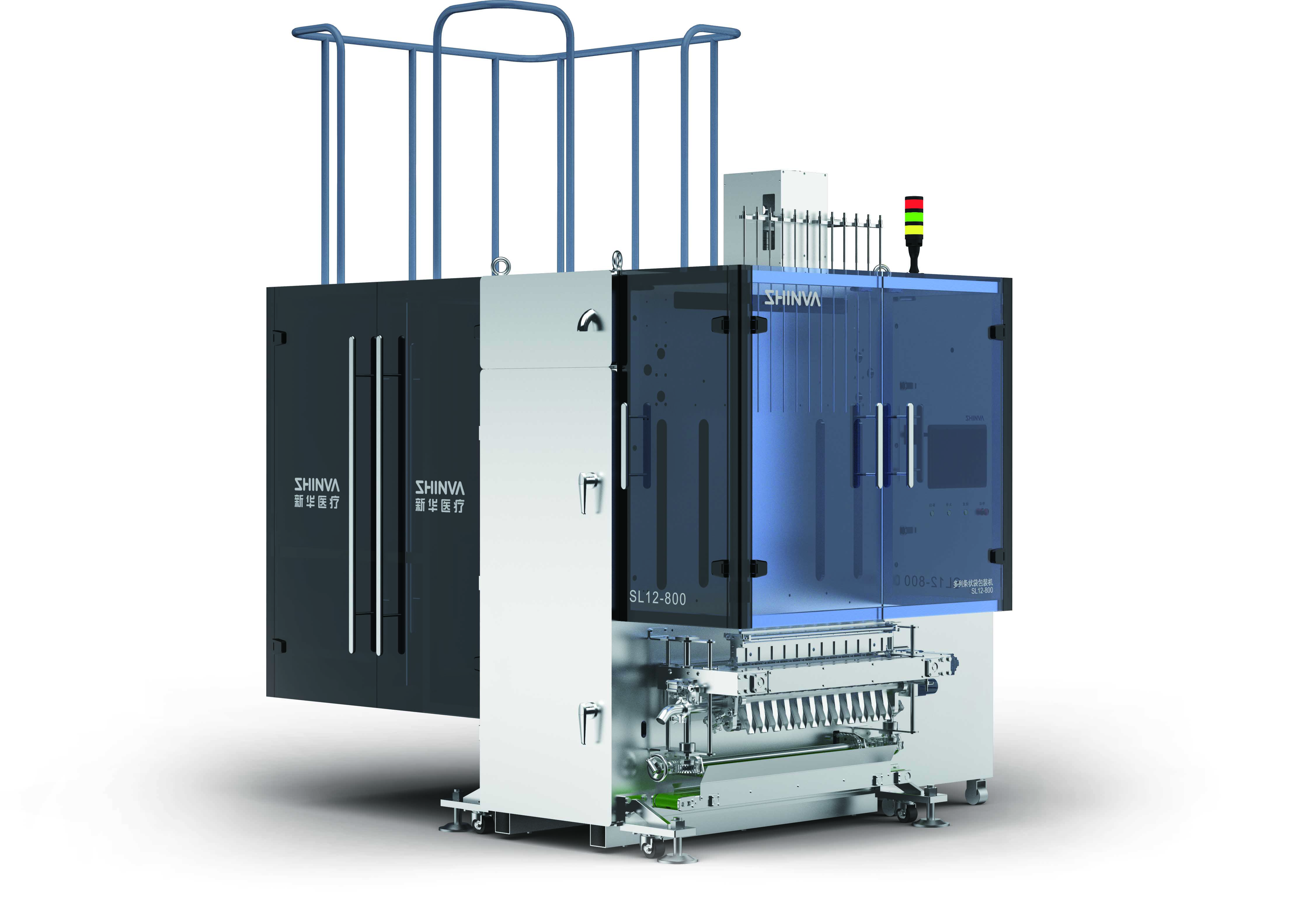

产品简介Product Introduction

本设备是针对口服液、糖浆、果酱等液体物料,自主研发设计的自动化包装机。可自动完成上料、打码、制袋、灌装、封口、分切、输出等工序,后端可配套计数整理、自动物流、通风式水浴灭菌器、自动装盒机等设备,实现产品高效、高质、安全自动化生产。通过工程设计、设备采购、核心设备设计及制造,现场安装调试及项目管理的全套服务,为客户打造“理想工厂”。

This equipment is an automatic packaging machine independently developed and designed for oral liquid, syrup, jam and other liquid materials. It can automatically complete such processes as feeding, coding, bag making, filling, sealing, cutting and output. The back-end can be equipped with counting and sorting, automatic logistics, ventilated water sterilizer, automatic cartoning machine and other equipment to achieve efficient, high-quality and safe automatic production. Through a full range of services including engineering design, equipment procurement, core equipment design and manufacturing, on-site installation, commissioning and project management, we will create an "ideal factory" for customers.

产品优势Product Advantages

配置激光测距,可实现无膜报警;

Laser ranging is configured, if there is no film, an alarm is given.

自动压膜对版,可实现快速膜卷更换;

Automatic film pressing and plate matching can realize rapid film roll replacement;

实现在线、多行、紫外激光打码,字迹清晰;

Realize online, multi-line, UV laser coding with clear handwriting;

伺服驱动主动滚刀切割膜卷,膜整齐无偏差;

Servo driven active hob cuts the film roll, and the film is neat without deviation;

伺服柔性焊接,模具单独加热控制,焊接质量可靠;

Servo flexible welding, mold heating control alone, reliable welding quality;

离子风在线清洗,杜绝产品粉尘、颗粒污染风险;

Ionic air online cleaning to eliminate the risk of product dust and particle pollution;

采用网纹面压合,冷却压纹密封性强,网纹清晰;

The reticulated surface is used for pressing, and the cooling embossing has strong sealing property and clear reticulated lines;

PID温控技术,温度偏差±2℃,焊接强度稳定;

PID temperature control technology, temperature deviation ±2℃, stable welding strength;

全套进口高端运动控制器,各执行机构全部采用伺服电机驱动,性能稳定。

A full set of imported high-end motion controllers, all actuators are driven by servo motors, with stable performance.